Premium Capillary Mass Flow Meters and Mass Flow Controllers for Gases

The SmartTrak® thermal mass flow meters and mass flow controllers are true multi-gas digital MFC designed to deliver smooth, stable, accurate, and repeatable gas mass flow control you can rely on, every time.

Note: SmartTrak® series units are available in Europe only!

- Gas Mass flow meter and controller based on capillary technology with up to 0.5% full scale accuracy

- All wetted parts stainless steel, 0.8 Ra µm electro polished surfaces. Cleanroom assembly possible

- Ranges from 0-10 mln/min to 0-500 ln/min

- Every units has 10 pre-programmed gases, customer selectable

- Choice of customer selectable engineering units, gases, outputs, range, etc.

- Due to the advanced engineering, accuracy for every gas selected

- Operating pressure standard 35 barg

- Suitable for most corrosive and aggressive dry and clean gases

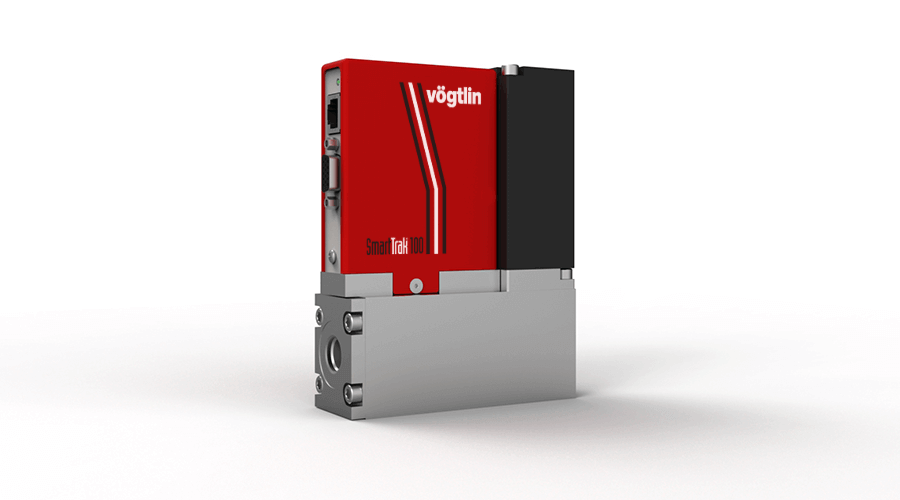

- Optional local display and local setpoint/configuration

- Most analogue and RS232 communication standard on each unit

- Active temperature compensation for temperature independent operation

- Strong direct driven valve

- Optional Modbus communication

- Modbus module with analogue input/outputs and I/O alarm contacts

- Wide choice of elastomers and valve seal materials

- Long term stability sensor

- Free configuration software for MS Windows

- Very low pressure differentials possible due to big valve

- Every unit calibrated with Primary NIST traceable high accuracy reference standard

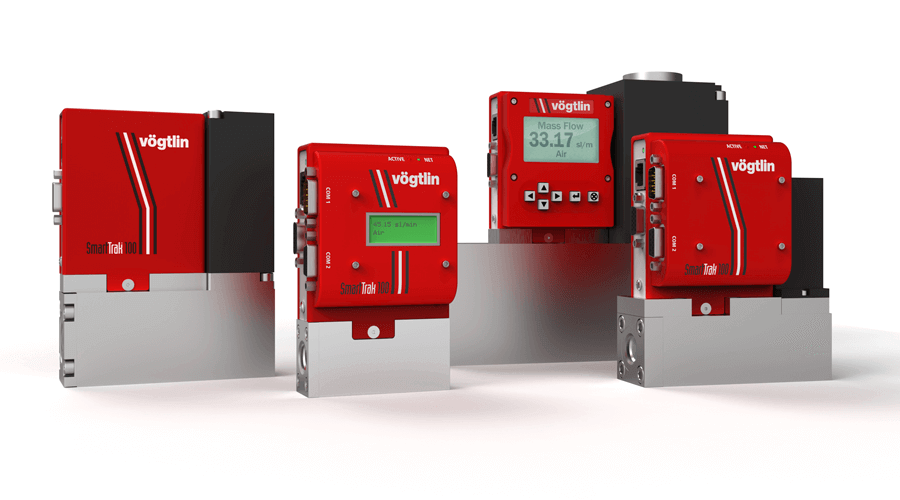

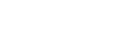

Device Types SmartTrak® series

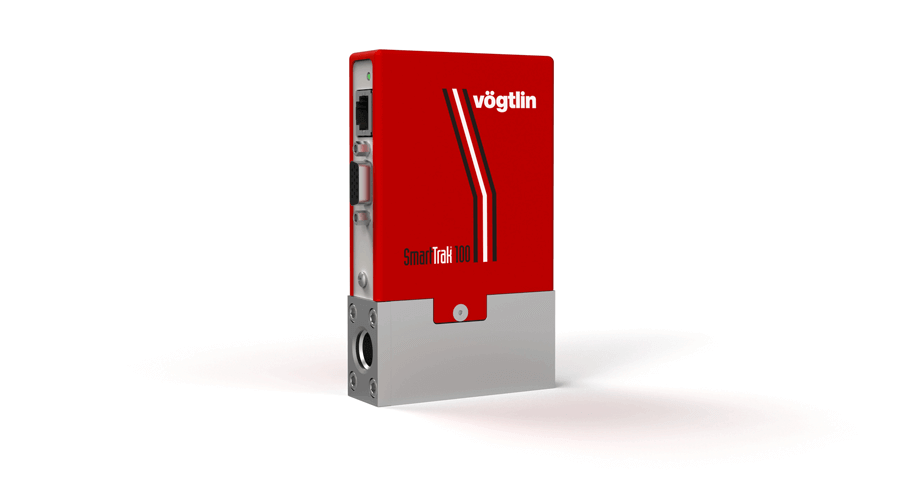

SmartTrak® 100L (Low Flow)

Capillary Mass Flow Meters and Mass Flow Controllers

Flows from 0-10 mln/min to 0-50 ln/min

SmartTrak® 100M (Medium Flow)

Capillary Mass Flow Meters and Mass Flow Controllers

Flows from 0-20 to 0-200 ln/min

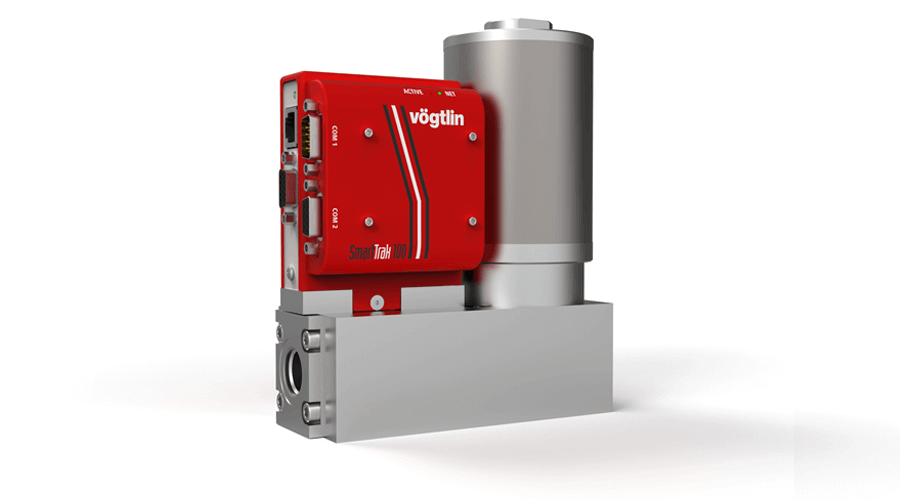

SmartTrak® 100H (High Flow)

Capillary Mass Flow Meters and Mass Flow Controllers

Flows from 0-500 ln/min

Interfaces SmartTrak® series

SmartTrak@ series

Standard version with analog signals and digital RS232 interface

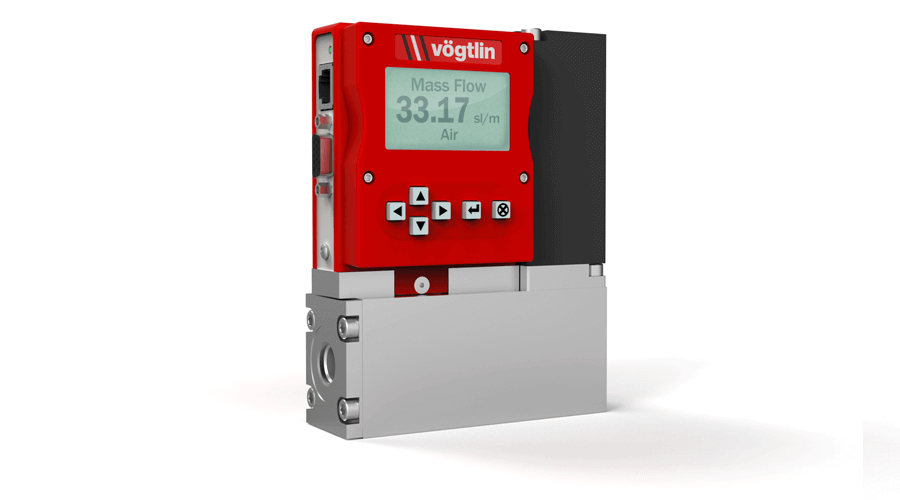

SmartTrak@ series / Pilot Module

Optional version with local display interface (Pilot Module)

SmartTrak@ series / Remote Pilot Module

Optional version with remote display interface (Remote Pilot Module)

SmartTrak@ series with Modbus RTU

Optional version with Modbus RTU interface (RS485)

SmartTrak@ series with Modbus/Display

Optional version with Modbus RTU interface (RS485) and local display

Technical Specifications SmartTrak® series

| Measuring ranges | |

|---|---|

| Air/Full scale freely selectable | SmartTrak® 100L (Low Flow): 0-10 mln/min to 0-50 ln/min SmartTrak® 100M (Medium Flow): 0-20 to 0-200 ln/min SmartTrak® 100H (High Flow): 0-100 to 0-500 ln/min Flow ranges specified are for an equivalent flow of nitrogen at 1013.25 mbara (760 mm Hg) and 0°C (32°F) For other gases and reference conditions please contact the factory. |

| Instrument versions | |

| “Standard” The economic solution |

Accuracy: ± 1.0% of full scale* Turndown ratio: 1 : 50 (Controller), 1 : 100 (Meter) |

| “Hi-Performance” With high accuracy |

Accuracy: ± 0.5% of full scale* Including 10 point certificate Hi-performance is only possible for: Flow range: up to 50 slpm or nlpm (valid from 10 to 100% of the calibrated range) Gases: Air, Nitrogen, Helium or Argon Other gases and flow: Contact the factory Only valid for units up to an operating pressure of 10 barg and over the temperature range 10°C to 30°C in a horizontal position. The accuracy is only guaranteed under calibrated conditions and is only valid for a period of 6 months after the date of calibration. Valid for 10 to 100% of FS. *An additional error of ±0.25% may apply for analogue signals |

| Performance Data | |

| Media (real gas calibration) | All gases and gas mixtures that are compatible with the selected material. There might be limitations to some corrosive gases |

| Response time | 2 seconds (typical) to within ± 2% of final value (includes settling time), faster or slower available upon request (controllers only) |

| Repeatability | ± 0.2% of full scale (according to SEMI standard E56-0309) |

| Longterm stability | Typical < 2% of measured value / year |

| Power supply | Mass Flow Meters: 15-24 VDC ±10%, (230 mA, regulated) Mass Flow Controllers: C100L: 24 VDC ±10% (500 mA, regulated) C100M: 24 VDC ±10%, (800 mA, regulated) C100H: 24 VDC ±10%, (1260 mA, regulated) (ripple should not exceed 100 mV peak-to-peak) |

| Operation pressure | 0-35 barg (0 – 500 psig) |

| Temperature (environment/gas) | 0 – 50°C (32 – 122°F) |

| Pressure sensitivity | <0.15% / bar (<0.01% / psi) FS (typical N2, horizontal mount) |

| Temperature sensitivity | <0.05% FS measuring range type per 1°C (<0.025% per 1°F) |

| Warm-up time | < 15 min for full accuracy |

| Materials | |

| Meter all wetted metal parts | 316SS (1.4404) |

| Controller body/sensor materials | 316SS (1.4404) |

| Controllers valve post materials | C100L/C101: 316SS/410SS/430SS (1.4404/1.4006/1.4016) C100M: 416SS/430SS (1.4005/1.4016) C100H: 316SS/416SS/430SS (1.4404/1.4005/1.4016) |

| Electronic Housing | Powder coated steel |

| Seals | FKM (Viton®) Options: Neoprene |

| Valve seals | FKM (Viton®) Options: Neoprene, Kalrex® |

| Integration & Installation | |

| Output signals analog | Linear 4–20 mA or 0-20 mA, 500 ohms maximum loop resistance and one of the following (user selectable): Linear 0–5 VDC, 1000 ohms minimum load resistance Linear 0-10 VDC, 1000 ohms minimum load resistance Linear 1-5 VDC, 1000 ohms minimum load resistance |

| Setpoint signals analog | Analog (choice of one, user selectable): Linear 4–20 mA, 0-20 mA. 0–5 VDC, 0-10 VDC, 1-5 VDC |

| Output signals digital | RS232 Optional: RS485; Modbus RTU (Slave) |

| Process connection | Fittings included. Options: Swagelok® (Compression), VCR, VCO, NPT |

| Inlet section | None required |

| Electrical connection | D-15 High density plug (15 pins) female |

| Mounting orientation | All orientations are possible but must be defined at time of order |

| Safety | |

| Burst pressure | 52 bar (240 psi) |

| Leak rate | < 1 x 10-9 mbar l/s He |

| Ingress protection class | IP20 |

| EMC | EN 61326-1 |

| ATEX Certification | None |

SmartTrak® series Configuration Software

Communication with the SmartTrak® series over RS232

Recommended cables: 100-CRN + Optional 100-SerialUSB

SmartTrak® series COMPOD Configuration Terminal Software

To set the communication settings in a COMPOD a terminal software is required.

The free software PuTTY or Windows HyperTerminal can be used.

For further instructions see chapter 7 on the COMPOD operating instructions.

Recommended cables: 100-CRC and RS485 to USB converter

SmartTrak® series DLL Files

The SmartTrak® DLL helps the customer to create their own software, exactly according to their specifications.

The DLL handles all communication, synchronization and guards line stability.

For Labview drivers please contact the factory.