The gas control system that grows with your needs!

Vögtlin is offering all kinds of Bioreactor upgrade modules specifically suited for your application. Systems that make your system, repeatable, consistent and independent to external influences like pressure and temperature changes. Below is an example of the most used solution. If you would like to have a suggestion for your specific needs please provide us with you details and we will free of charge make a proposal.

Customized OEM Flow Solutions by Vögtlin

Gas control solutions

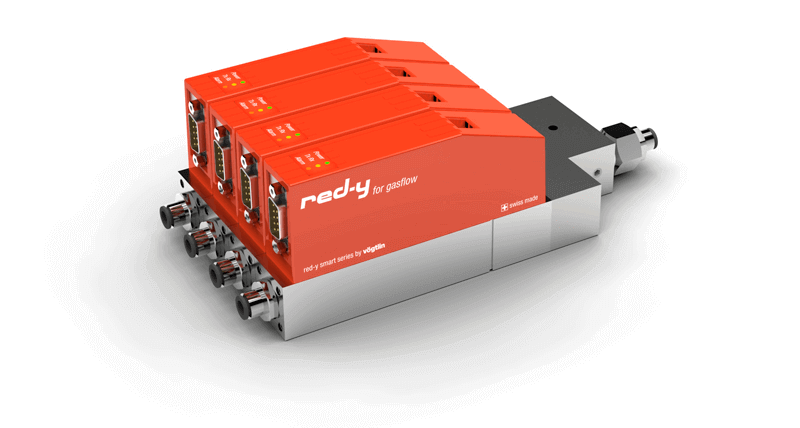

Vögtlin supplies complete gas mixing solutions of mass flow controllers including all required inlet and outlet configurations that can directly be connected to your reactor. In these sets we can optionally integrate all kind of accessories like pressure sensors, non-return valve, inlet filters, shut-off valves, etc.: Plug-and-play.

The wetted materials of this block can be anodized aluminum eco solutions or advanced 3.1 certified, FDA-compliant stainless steel. It is also possible to supply IP67 or Ex approved units.

Most customers prefer to keep their VA meter in their gas supply so that there is a visual confirmation of flow. As long as there is enough inlet pressure, this is no problem. However you might see considerable differences between them, especially if the pressure varies a lot. Due to the insensitivity in pressure and temperature the mass flow controller will be more accurate than the VA meter.

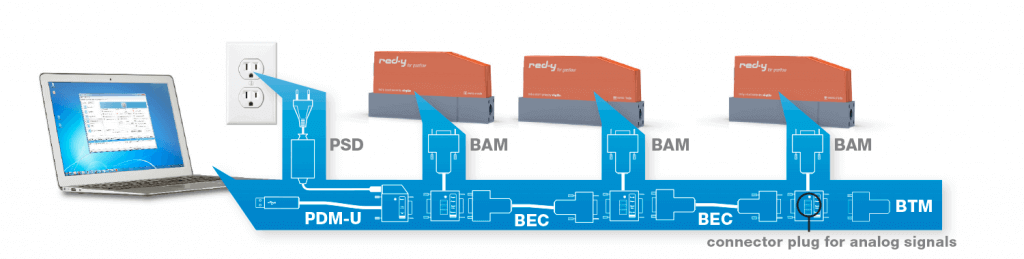

Cabling

Once the mechanical block is defined we can create the cabling system for the controls and power supply of your MFC’s. You can make your own cables (Use D9 plugs) but alternatively Vögtlin has a modular system with which you quickly and simply build a complete cable system. The system is suitable for analogue and digital control.

In the example diagram shown the following cables are used:

This is only one of the many possibilities of our cable system, other systems (f.i. for Profibus MFC’s or gateways to Ethernet) are also available.

Control solutions

There are several methods to control the gas flows and change the ratios.

- Manual setting

- Control box

- Standard software

- Analog

- Digital

More details on each of these options below:

Manual setting: If you choose to select the integrated display and setpoint buttons, you can adjust the required flow on the MFC’s themselves with push buttons.

This solution can also be added to most other control systems in case you need a back-up system in case the main system fails or if you want to have a simple way to override a system.

Control box: The Vögtlin control box offers an integrated power supply and a color touch screen to not only to give individual set points, but also have functions like an integrated ratio control system and storage of pre-defined recipes. You can connect up to 10 units to one PCU-10 box.

Standard software: Once you set-up your cabling and plug in your USB connector into your computer you can control and configure all the connected units through our free software get red-y. The mass flow controllers are all connected with one USB connection to your PC. Once you have installed the software, you can set and read flows and temperatures, create mixtures, and log all variables so you can review them in Excel™ afterwards. You can change the ranges and gasses for which the MFC is suited and optimize their operation, depending on your specific application. There are two add-on’s to the basic program, one offers the above mentioned data collection and gas mixing software and the other offer the ability for the users to calibrate the units themselves.

Analog: If you already have a PLC or control system and use analog signals available, you can use the standard analog setpoints and output signals of the mfc. Most types of analogue signals are available on the smart instruments, (i.e. 0-5 Vdc, 4-20 mA, 0-10 Vdc etc.). The required analogue signal can be set with the free above mentioned software.

Digital: If you already have a control system, like an embedded PC or a PLC you can communicate digitally to the mass flow controllers. Standard we use the straightforward and most commonly used Modbus serial communication. You can also request Profibus as an option.

We supply several programming examples of drivers (i.e. VI’s for LabVIEW™) and a thorough digital manual so that implementation is breeze. If you need support, our software specialists will be happy to support you.

Digital also has the advantage that you can monitor and use other variables. For instance you can look at the valve load. If the inlet pressure becomes lower (e.g. a leak or gas bottles getting empty) or if there is a blockage in the system, the valve load will change and an alarm can be activated before it becomes a critical problem.

Vögtlin develops and manufactures complete OEM solutions. So whatever your needs, Vögtlin has a solution for you.