Bioreactor Technology: How can you upgrade your Gas Flow Control?

In recent years we have an increasing demand for reliable, repeatable and flexible gas supply systems for bioreactors. This is due to the ever more demanding, critical and delicate processes in the bio-industry where VA meters are no longer suitable and mass flow controllers are improving the process.

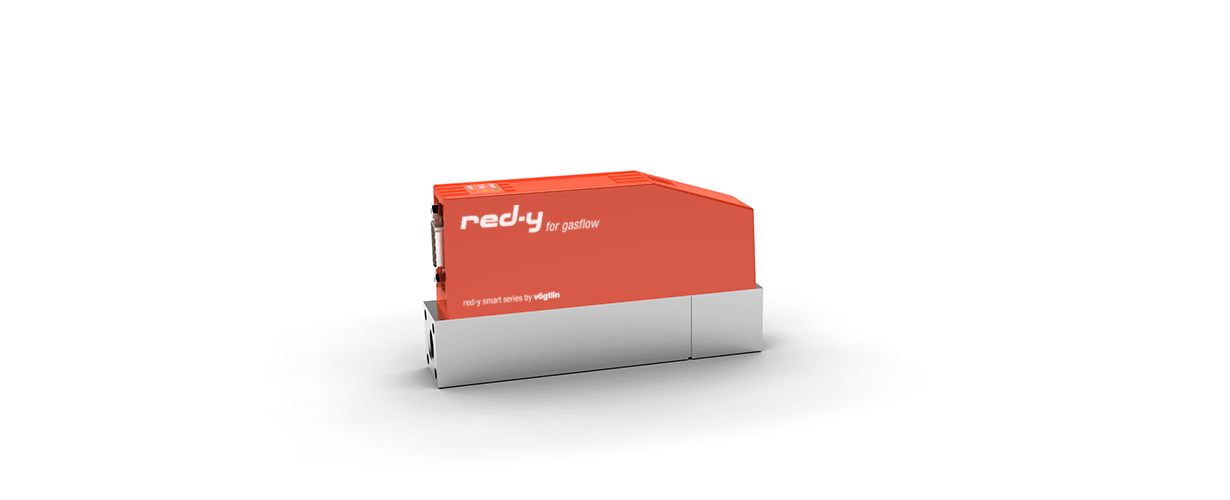

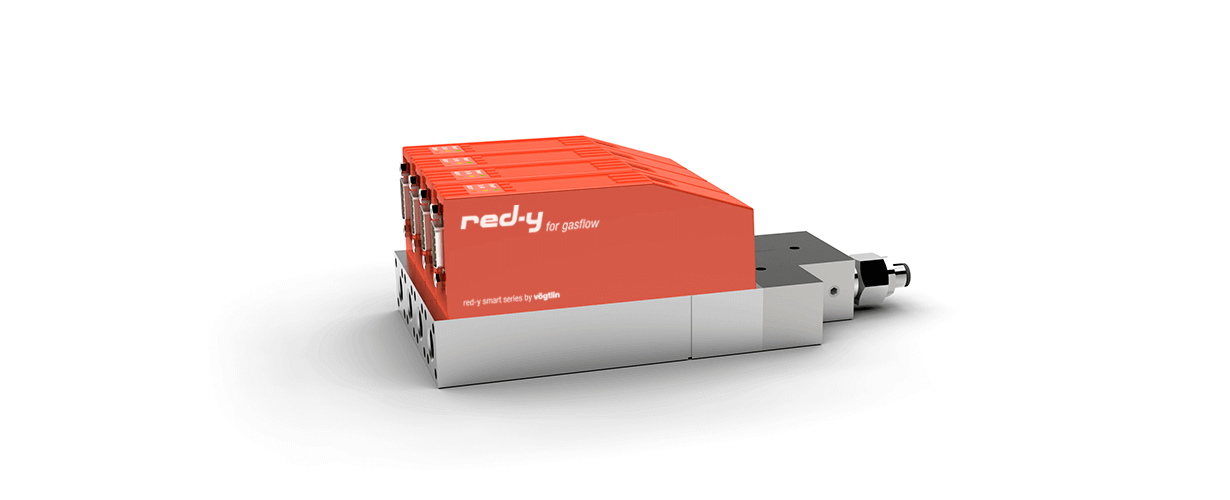

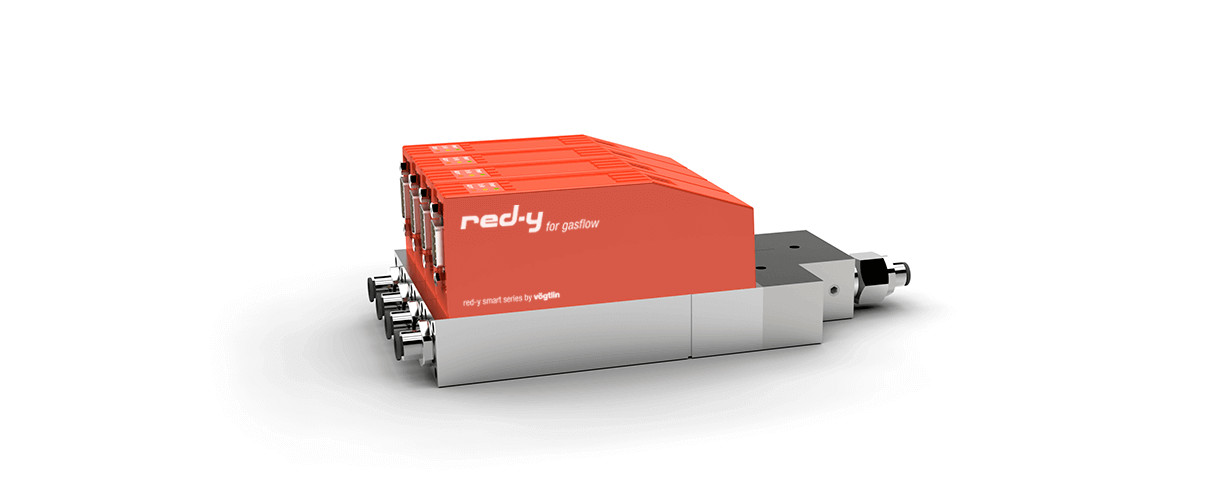

In this article we show that it is relatively simple to implement a ‹plug-and-play› upgrade solution with the Vögtlin modular system, based on your demands, requirements and budget.

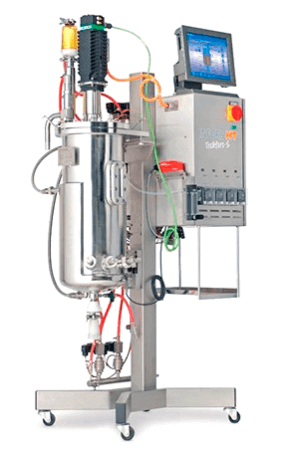

Bioreactor Techfors-S (courtesy of Infors AG) equipped with a red-y smart massflow controller.

«At Infors we strive to provide highly advanced bioprocessing solutions based on reliable hardware, intelligent control systems and innovative bioprocess platform software in order to create maximum value for our customers. The Vögtlin mass flow controllers fit perfectly into this concept and enable us to provide our customers with solutions for precise pO2 control at all times. Therefore, we’re happy to recommend Vögtlin to all our customers.»

Dr. Dirk Hebel, Product Manager Bioreactors, Infors AG

As an example the adequate supply of oxygen to the bioprocess is important. The metabolism of the microorganisms is dependent on the dissolved oxygen concentration, so that a precise control is desirable. Therefore the oxygen concentration must be lowered or increased as required by adding of either nitrogen or oxygen.

Another important variable is the the pH value. For microbial bioprocesses this is done with the addition of liquid acids and alkalis. For cell culture, on the other hand, one uses only liquid alkalis. The liquid acid can damage the cells so you use CO2 instead of liquid acid. There are many different bioreactor processes and each has it specific reason to use gases, but they all have in common that gas flow control plays an important and not to be underestimate role in the process. Gas needs to be measured and controlled on a reliable and safe way.

Traditionally these gas flows were done using manual VA-meters with integrated valves. But nowadays users want to automate their process. Some more demanding processes also require a higher performance (mainly repeatability). Due to these demands we often get the request to upgrade older VA-based gas supply systems to modern automated controls with this better performance.

Why are VA meter less suitable?

VA meters have no output signal and are not suitable for automatization of your process. They are extremely sensitive to changes in pressure and temperature, a small change creates a relative big error in the indicated mass flow. This uncertainty creates non-repeatability in your process. MFC’s measure true mass, independent of pressure and temperature, constantly providing a predefined mass flow.

About the Author:

About the Author:

Paul de Waal is Vögtlin’s Business Development Director.

Paul enjoys sharing his 30 years’ experience in thermal gas mass flow. For questions, comments or suggestions please contact him on p.dewaal@voegtlin.com