Flame control at the highest level

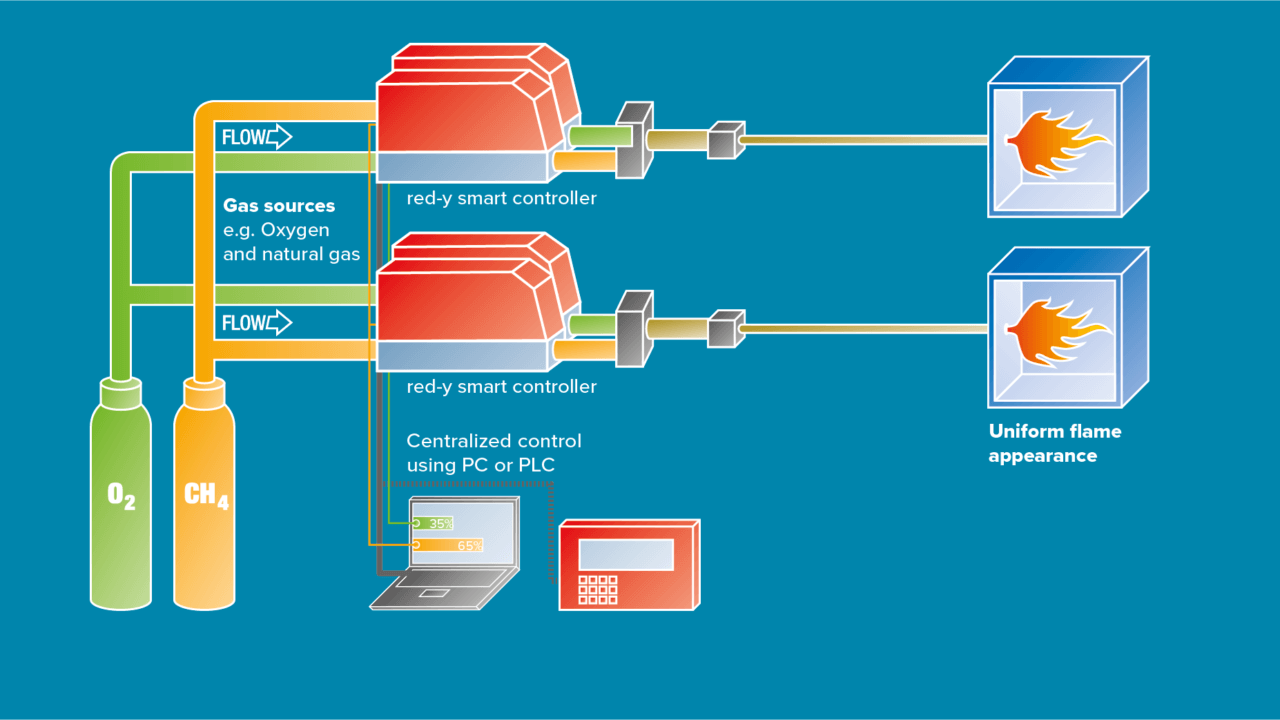

To ensure consistent quality in pharmaceutical glass production, the flame pattern must be constant and uniform.

This requires precise and accurate call-off of the gas dosing.

Application

There are tight specifications and high quality requirements for the production of small pharmaceutical bottles, vials and capsules made of glass.

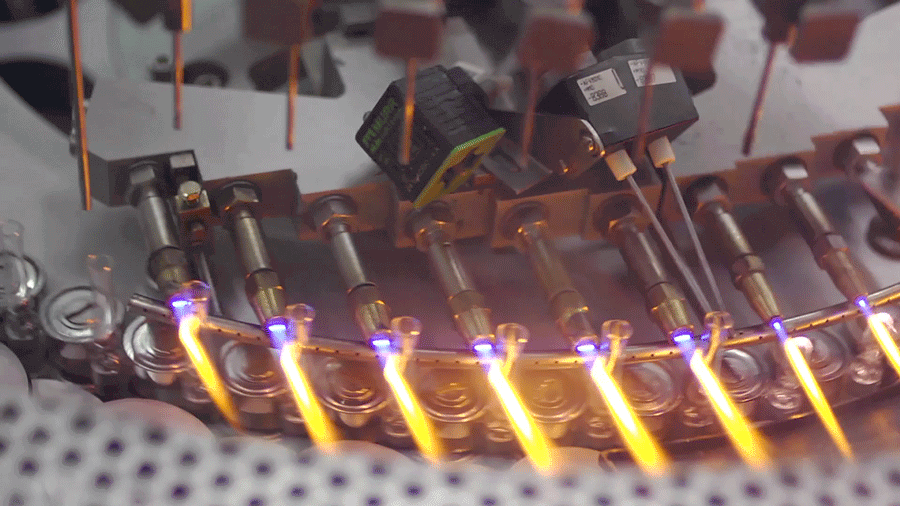

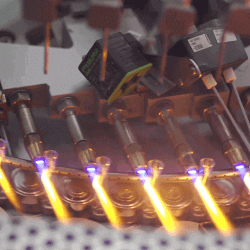

The pharmaceutical glass product is created from glass tubes about 2 meters long, which are fed into a machine. These are heated, shaped and cut into individual bottles.

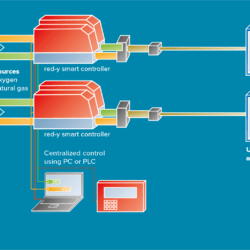

The flames that heat the glass are created by mixing a fuel with oxygen. Fuels can be hydrogen, propane, natural gas, etc. Sometimes air is added to lower the temperature.

Challenge

The challenge is to maintain constant and repeatable flames. If the pressure in the gas supply line or the temperature of the gas changes the ratio between the oxygen and the fuel will change and the flame will change. This will influence the quality of the product. If you have a manual system you have to constantly manually adjust the flame, but with mass flow controllers in the supply line of the critical flows the flame will always be optimized and startup will be a lot faster. Optimized settings also mean you save on gas consumption and improve your yield.

Only with consistent flames, you can generate consistent and repeatable products.

Solution

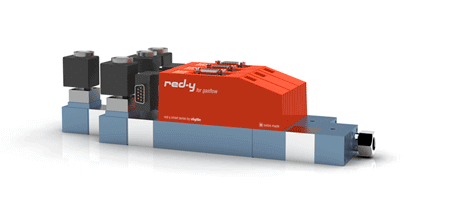

MEMS technology of the mass flow controllers offers fast response times of 500 ms*. Plug & play functionality without warm-up phases improves user productivity.

Vögtlin mass flow controllers compensate for changes in ambient or gas temperature through automatic temperature compensation. This significantly improves repeatability.

MEMS technology ensures long-term stability without deviations under the condition of a clean and dry gas supply. Measurement failures caused by ambient and gas temperature are significantly reduced by the dual temperature calibration.

*depending on device configuration & according to SEMI standard E17-1011, 5-100% of range under optimized conditions.

Main Features

- High repeatability & reliability

- No zero offset

- High long term stability

- Short response time

- Safe & fast control

- Compact unit with high quality components

- Efficiency – no rejects and higher yields

- Savings in gas consumption

Available interfaces

- Analog

- Modbus RTU

- Profibus DP-V0/DP-V1

- Profinet

- EtherCAT

- EtherNet/IP