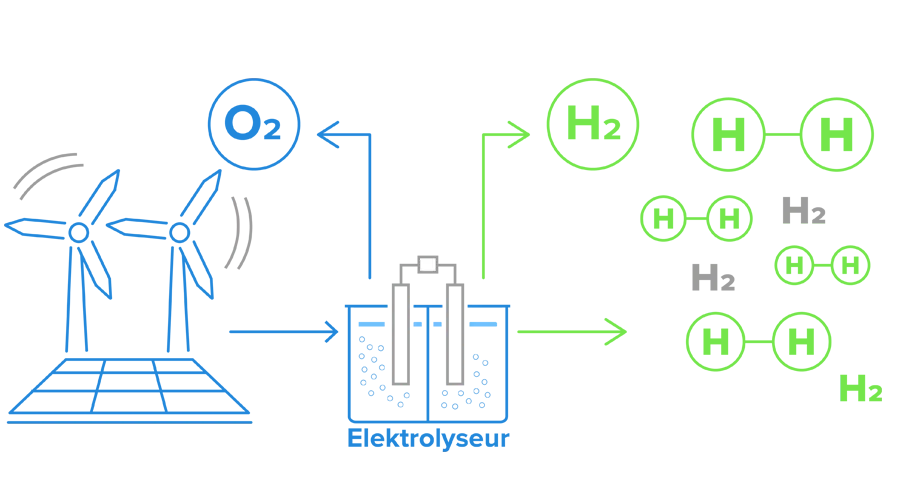

Electrolysers are technical devices that split water (H₂O) into its components hydrogen (H₂) and oxygen (O₂) using an electric current – a process known as electrolysis. They are at the heart of so–called green hydrogen production when the electricity used comes from renewable energy sources, such as wind or solar power.

LEANCAT (https://lean-cat.com/), a manufacturer and developer of hydrogen systems, including testing stations for electrolysers, conducted a study to determine how humidity affects the accuracy of thermal gas mass flow meters. Their findings showed that if the hydrogen’s dewpoint is above

-10°C, calibration errors become significant.

Based on these results, we strongly recommend drying hydrogen coming from a electrolyser to a dew point of -10°C or lower when using a thermal mass flow meter or controller. For optimal performance, the device should be calibrated with real hydrogen, offer a dynamic range of at least 1:100, provide excellent long-term stability, and exhibit a low pressure drop.

Vögtlin offers hydrogen flow solutions ranging from 0–0.01 to 0–2900 ln/min that meet these requirements.

In conclusion, drying hydrogen to a dew point of -10°C or lower is essential for accurate measurement.